Airtech x Sustainability

Airtech x Sustainability

Our Journey to

NET ZERO

At Airtech, we are dedicated to sustainability and are committed to making a positive impact on the world. Sustainability is not just a goal; it's a journey that we've embarked on, and we are taking concrete actions to reduce our environmental footprint and lead the industry in sustainable practices.

A Message From

Our CEO

At Airtech Advanced Materials Group, our commitment to social, environmental, and corporate responsibilities is unwavering. We are fully dedicated to investing in sustainable production and offering reduced fossil fuel products. Our promise extends to our employees and customers, where we uphold strict ethical and compliance standards.

As a family company, we set high expectations for ourselves. We recognize the need to lead our industry and exceed the expectations of our global workforce and customers worldwide. We embrace these diverse challenges with enthusiasm, and we eagerly look forward to not only meeting but exceeding our industry's goals.

Jeff Dahlgren, President & CEO

Our Four Key Pillars

Our sustainability mission is built upon four key pillars that guide our actions and decisions:

Carbon Neutrality & Energy Efficiency

Reducing our carbon footprint through energy efficiency and renewable energy adoption.

Innovative Green Technologies

Developing eco-friendly materials and manufacturing processes to reduce environmental impact.

Circular Design & Lifecycle

Creating products with waste reduction and responsible lifecycle management in mind.

Community Engagement

Inspiring future generations through educational partnerships and advocacy.

Our Plan

Our current sustainability initiatives include

In the initial phase of our sustainability journey (2024-2030), our focus is clear. We have set ambitious, measurable goals that align with our commitment to sustainability and decarbonization. These goals will mark the beginning of our roadmap to Net Zero by 2050.

However, our journey does not end here. We recognize the importance of evaluating our progress, making necessary adjustments, and learning from our achievements and setbacks.

Phase 1: 2024 - 2030

| Establishing the Foundation | Accelerating Sustainability | Continuous Improvement & Expansion | |

|---|---|---|---|

| Waste Stream Management & Recycling |

|

|

|

| Energy Efficiency |

|

|

|

| Carbon Offset & Reduction |

|

|

|

| Product Sustainability |

|

|

|

| Low Emissions Logistics |

|

|

|

Sustainability in Action

Discover how we are already paving the way forward in sustainability:

Collaboration with Oak Ridge National Laboratory

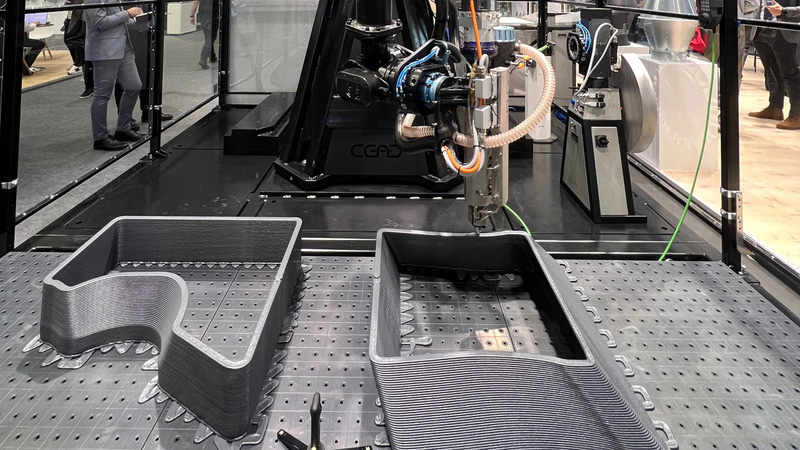

Airtech is at the forefront of sustainable additive manufacturing. Through our collaboration with Oak Ridge National Laboratory, we've transformed old carbon-fiber aerodynamic splitter molds, originally used in the 2022 Pikes Peak race, into something extraordinary. These molds have been recycled and repurposed using regenerated source material, allowing us to 3D print a new splitter mold. This innovative approach contributed to Brumos Racing Car's remarkable world record achievement at the 2023 Pikes Peak International Hill Climb.

Watch the video to learn more about our innovative partnership with Oak Ridge National Laboratory and how we're reshaping sustainability in composites. »

Airtech Announces NEW Sustainable Dahltram® T-100GF Resin

We are excited to introduce our latest breakthrough, Dahltram® T-100GF resin—a groundbreaking achievement in sustainable large-scale 3D printing. This innovative recycled grade thermoplastic polymer resin, designed for pellet-fed systems, signifies a significant stride towards enhancing sustainability in the industry. Click the link below to discover how Dahltram® T-100GF resin is shaping the future of large-scale 3D printing.