Airtech Advanced Materials Group Invests in a New Technology and a 10’ x 40’ LSAM 3D Printing Machine

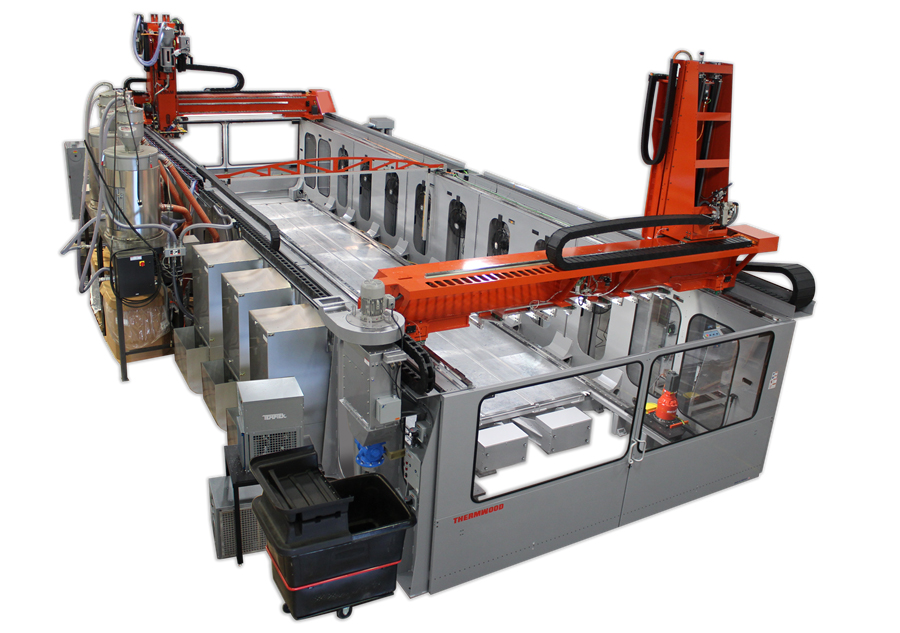

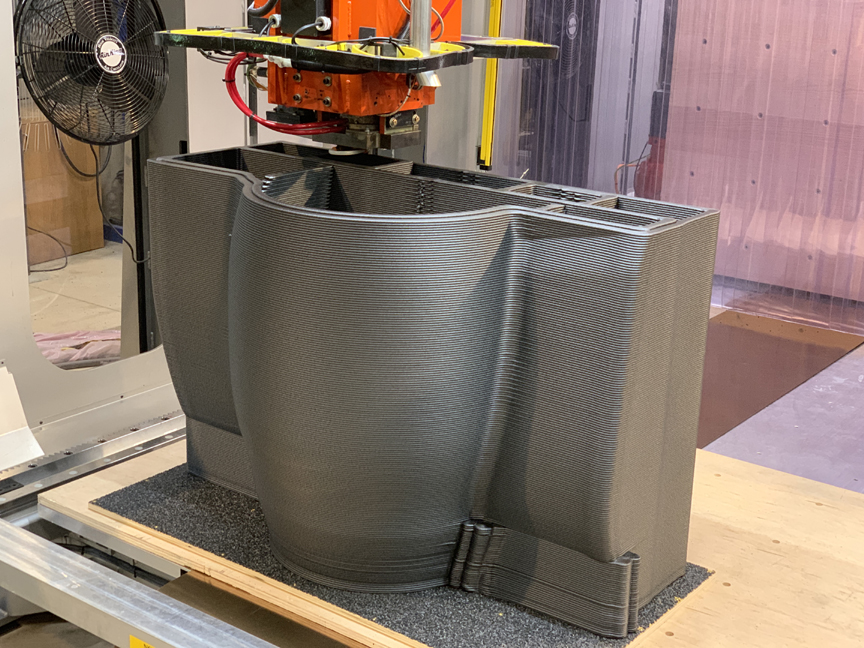

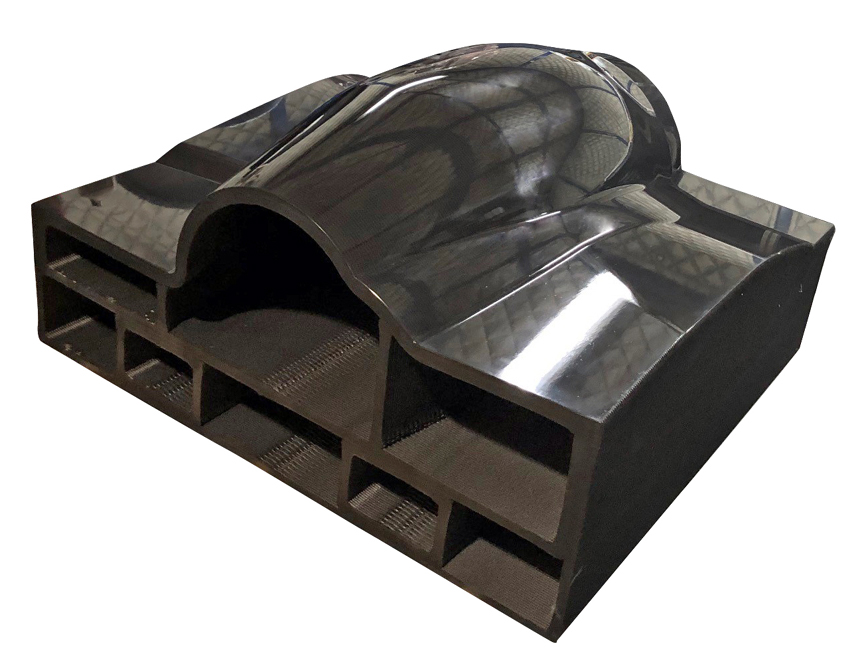

26 Sep, 2019Airtech Advanced Materials Group, the world’s largest manufacturer of vacuum bagging and composite tooling materials, has invested in new technology in the form of a Large Scale Additive Manufacturing (LSAM) 3D printing machine with integrated machining capability. The LSAM relies on thermoplastic extrusion, a core competency of Airtech with nearly 50 years of experience to build on. The LSAM can take tooling from conception to the shop floor significantly faster than conventional methods. Additive manufacturing uses almost the exact amount of material required, resulting in less touch labor and shorter lead times. Airtech believes that additive manufacturing is a game changer that will change the tooling manufacturing world, especially in the aerospace industry. Large-scale tooling in the form of trim fixtures, holding fixtures, and layup molds can be designed, tooled, and built faster without compromising on quality.

Airtech has invested in a 60,000 ft2 (5,574 m2) expansion at its Custom Engineered Products division in Springfield, TN. “Airtech has been an extrusion company for over 45 years and is ready to take the next step into extrusion involving additive manufacturing, 3-D printing. This type of extrusion is similar to what we are doing now with films but will be used to create new tooling with internal heating (OOA) on a large scale, up to 40ft long. We are developing new technologies to help our partners reduce cost and increase productivity,” said Jeff Dahlgren, President/CEO of Airtech Advanced Materials Group.

Airtech is dedicated to driving innovation in aerospace, including several trademarked products and patent pending processes for additive manufacturing. With both room temperature and high temperature material offerings, Airtech sits poised to meet the demands of its growing markets, ready to serve its customers. “We are excited to be able to offer numerous new additive manufacturing services and solutions to our customers to further solidify our stance as a leading technical partner in composites,” said Gregory Haye, Director of Additive Manufacturing, Airtech Advanced Materials Group.